Key Takeaways

- The Digital Supply Chain Market was valued at USD 19.57 billion in 2024 and is expected to grow to USD 42.22 billion by 2034, at a CAGR of 7.99%, driven by AI adoption, cloud computing, and the growing need for real-time data across global operations.

[1] - Over 77,300 enterprises worldwide implemented at least one form of digital supply chain technology in 2024, up from 52,800 in 2022, showing accelerated adoption across manufacturing, retail, and logistics sectors.

[2] - A Gartner survey of 419 supply chain leaders in June 2024 confirmed that AI (including machine learning) and generative AI are now the top digital supply chain investment priorities across all regions and industries.

[3] - McKinsey analysis shows that supply chain disruptions cost, on average, 45 percent of one year’s cash profit, and an estimated 86 percent of companies are now investing in supply chain transformation to respond to these disruptions.

[4] - Cloud-based supply chain solutions accounted for 64 percent of total digital transformation deployments in 2024, while over 38 percent of global suppliers used real-time data tracking to monitor shipment and inventory status, up from 29 percent in 2021.

[5] - The global Supply Chain IoT Market was valued at USD 83.16 billion in 2024 and is expected to reach USD 346.8 billion by 2032, growing at a CAGR of 19.54 percent, fueled by sensor-based tracking, connected logistics, and AI integration.

[6]

The way businesses move goods from one place to another has changed more in the last five years than it did in the previous fifty. Factories, warehouses, shipping lanes, and retail shelves are now connected by a web of data, software, and smart devices. This shift, commonly called supply chain digital transformation, is not just about buying new technology. It is about rethinking how every step of the supply chain works, communicates, and reacts to problems.

Think of the global supply chain like a massive relay race. Raw materials pass from mines to factories, from factories to warehouses, and finally to your doorstep. If even one runner stumbles, the whole team falls behind. For decades, businesses relied on phone calls, spreadsheets, and gut feelings to keep this race moving. But when COVID-19 hit, when ships got stuck in canals, when droughts shut down shipping routes, and when wars disrupted trade, it became clear that old methods were not enough. That is why modern supply chain solutions have become essential for businesses that want better visibility, faster response times, and stronger risk control. Companies that had invested in digital transformation in supply chain operations recovered faster. Those who had not were left scrambling.

Today, this transformation is no longer optional. Whether you run a small online store or a Fortune 500 company, the pressure to digitalize is real. Customers expect faster delivery. Regulators demand transparency. Competitors are already using AI, IoT, and blockchain to move faster and smarter. And according to a 2024 MHI Annual Industry Report, 55 percent of supply chain leaders are investing in technology and innovation, with 42 percent planning to spend over $10 million.

In this blog, we will walk through every important part of supply chain digital transformation. You will learn what it means, what technologies power it, how companies use it to gain visibility and control risk, what challenges come with it, and what the future holds. Everything here is based on real data, real examples, and real industry reports. Let us get started.

What Is Supply Chain Digital Transformation?

Supply chain digital transformation is the process of using modern technology to improve how goods are sourced, produced, stored, transported, and delivered. It involves replacing manual, paper-based, and siloed processes with connected digital systems that share data in real time. The goal is simple: make the supply chain faster, smarter, and more prepared for the unexpected.

This is not the same as just buying a new software tool. Digital supply chain transformation means changing the way a business thinks about its operations from the ground up. It means connecting every part of the chain, from the raw material supplier to the end customer, through a single digital thread that everyone can see and act on.

The reason this matters so much today is that supply chains have become incredibly complex. A single smartphone contains parts from over 40 different countries. A clothing brand may source cotton from India, dye it in Bangladesh, stitch it in Vietnam, and sell it in the United States. When any link in this chain breaks, the ripple effects can cost millions. McKinsey analysis shows that supply chain disruptions cost, on average, 45 percent of one year’s cash profit. That is nearly half of everything a company earns in a year, wiped out by problems in the supply chain.

This is why 86 percent of companies are now investing in supply chain transformation, according to McKinsey. The shift is happening across industries, from automotive and electronics to food, pharmaceuticals, and retail.

The Market Landscape: How Big Is This Shift?

To understand the scale of supply chain digitalization, you just need to look at the numbers. The Digital Supply Chain Market was valued at USD 19.57 billion in 2024. It is projected to grow to USD 42.22 billion by 2034 at a CAGR of 7.99 percent. This growth is not coming from one technology or one region. It is being driven by cloud computing, artificial intelligence, IoT sensors, and blockchain across North America, Europe, and the Asia Pacific.

North America leads the charge, with over 28,000 enterprises deploying digital supply chain technologies in 2024 alone. Europe contributed over 21,300 cloud-based supply chain deployments. And Asia Pacific saw a 35 percent increase in companies adopting integrated distribution and tracking solutions.

The manufacturing sector holds the largest share of this market at around 28.5 percent. Retail and e commerce is growing the fastest at a CAGR of 8.7 percent. And sectors like healthcare, energy, and government are also catching up as they face their own unique supply chain challenges.

At the same time, the global Supply Chain Management Software market was valued at USD 19.0 billion in 2024 and is expected to reach USD 22.9 billion by 2030. The supply chain software space is evolving from simple inventory trackers into complex platforms that handle everything from procurement to last-mile delivery, powered by AI and real-time analytics.

Recommended Reading:

Core Technologies Powering Supply Chain Digital Transformation

Supply chain innovation does not happen by accident. It is powered by a set of core technologies that work together to create a connected, intelligent, and responsive supply chain. Let us break down the most important ones.

1. Artificial Intelligence and Machine Learning

AI is the brain behind modern supply chains. It analyzes massive amounts of data to forecast demand, optimize routes, detect fraud, and automate decision-making. The AI in the supply chain market is projected to grow from USD 9.15 billion in 2024 to USD 40.53 billion by 2030 at a CAGR of 28.2 percent.

A Gartner survey of 419 supply chain leaders in June 2024 confirmed that AI and generative AI are the top digital supply chain investment priorities. Top-performing organizations are using AI to optimize their processes at more than twice the rate of their lower-performing peers. In practice, AI is being used for demand planning, inventory optimization, predictive maintenance, supplier evaluation, and logistics automation. McKinsey found that 65 percent of organizations were regularly using generative AI in 2024, nearly double the percentage from ten months earlier.

2. Internet of Things (IoT)

IoT devices are the eyes and ears of the supply chain. Sensors, RFID tags, GPS trackers, and smart devices collect real-time data on the location, condition, and movement of goods. The global Supply Chain IoT Market was valued at USD 83.16 billion in 2024 and is expected to reach USD 346.8 billion by 2032 at a CAGR of 19.54 percent.

In 2024, more than 17,500 organizations incorporated IoT sensors for real-time shipment and warehouse monitoring. Companies using IoT-driven inventory management have reported up to 30 percent reductions in stockouts and waste. IoT also plays a key role in cold chain logistics, where temperature-sensitive products like vaccines and fresh food need constant monitoring during transit.

3. Blockchain Technology

Blockchain provides a tamper-proof, decentralized ledger that records every transaction in the supply chain. This makes it perfect for tracking the origin and movement of goods, verifying authenticity, and preventing fraud. The global blockchain supply chain market was valued at USD 1,171.6 million in 2024 and is expected to reach USD 33,251 million by 2033 at a CAGR of 39.7 percent.

Companies like Walmart and Nestle already use blockchain to trace food products from farm to shelf. IBM’s Food Trust network enables consumers to scan a code and see exactly where their food came from. Smart contracts on blockchain automate payments and compliance checks, removing the need for middlemen and reducing errors.

4. Cloud Computing

Cloud platforms are the foundation that holds everything together. They allow companies to store, process, and share supply chain data without investing in expensive on-premises hardware. Cloud-based supply chain solutions accounted for 64 percent of total digital transformation deployments in 2024. The flexibility of cloud systems allows businesses of all sizes, from startups to multinational corporations, to access advanced tools without massive upfront costs.

5. Digital Twins

Digital twins are virtual replicas of physical supply chain assets, processes, or entire networks. They allow companies to simulate “what if” scenarios and test changes before implementing them in the real world. McKinsey reports that 70 percent of C-suite technology executives at large enterprises are already exploring and investing in digital twins. In 2024, over 14,000 manufacturing units used digital twin technology to simulate and optimize their operations. These twins can increase decision-making speed by up to 90 percent.

6. Robotic Process Automation (RPA)

RPA handles repetitive, rule-based tasks like order processing, invoice matching, and data entry. By automating these tasks, businesses free up their human workforce to focus on strategic decision-making. Supply chain automation through RPA reduces processing time, lowers error rates, and cuts operational costs. According to Grand View Research, the global warehouse robotics market is projected to reach $17.29 billion by 2030, growing at a CAGR of 19.6 percent.

Supply Chain Visibility: Seeing the Full Picture

Supply chain visibility is the ability to track every product, shipment, and transaction across the entire supply chain in real time. Without visibility, you are essentially flying blind. You do not know where your goods are, when they will arrive, or if something has gone wrong until it is too late.

This is a bigger problem than most people realize. A McKinsey survey found that 45 percent of respondents either have no visibility into their upstream supply chain or can see only as far as their first-tier suppliers. That means almost half of all businesses have no idea what is happening beyond the companies they deal with directly. If a sub supplier in a different country faces a problem, these businesses would not know about it until the delay hits them.

The Supply Chain Visibility Software Market is estimated at USD 1,739.31 million in 2025 and is expected to reach USD 12,941.61 million by 2034 at a CAGR of 24.98 percent. This rapid growth reflects how urgently businesses need this capability. More than 78 percent of global manufacturers reported visibility gaps across their supplier networks in 2024, and over 64 percent reported increased disruption frequency.

Real-time supply chain data integration increased by 53 percent in the last year. And 71 percent of logistics leaders are now prioritizing end-to-end tracking capabilities. The tools making this possible include IoT sensors for physical tracking, cloud platforms for data sharing, AI for predictive alerts, and blockchain for verified record keeping.

When companies achieve full visibility, the results are powerful. They can reroute shipments before delays happen, adjust production schedules based on real demand, identify bottlenecks in seconds, and give customers accurate delivery estimates. Nearly 8 in 10 businesses were implementing end-to-end dashboards for full supply chain visibility in 2023, a significant jump from just 37 percent the year before.

Key Technologies and Their Supply Chain Impact

| Technology | Primary Function in Supply Chain | Market Value / Growth Data |

|---|---|---|

| Artificial Intelligence | Demand forecasting, route optimization, supplier evaluation, and automated decision making | USD 9.15B (2024) to USD 40.53B (2030), CAGR 28.2% |

| Internet of Things (IoT) | Real-time tracking, condition monitoring, warehouse automation, cold chain management | USD 83.16B (2024) to USD 346.8B (2032), CAGR 19.54% |

| Blockchain | Tamper-proof record keeping, product traceability, smart contract automation, and fraud prevention | USD 1,171.6M (2024) to USD 33,251M (2033), CAGR 39.7% |

| Cloud Computing | Data storage, multi-party collaboration, cost-effective infrastructure, and global accessibility | 64% of all supply chain digital deployments in 2024 |

| Digital Twins | Scenario simulation, process optimization, predictive modeling, risk assessment | 70% of C-suite tech execs are investing, and 14,000+ manufacturing units are being used in 2024 |

| Robotic Process Automation | Order processing, invoice matching, data entry, repetitive task automation | Warehouse robotics market to reach $17.29B by 2030, CAGR 19.6% |

| Visibility Software | End-to-end shipment tracking, supplier transparency, predictive alerts, and exception management | USD 1,739.31M (2025) to USD 12,941.61M (2034), CAGR 24.98% |

Supply Chain Automation: Doing More with Less

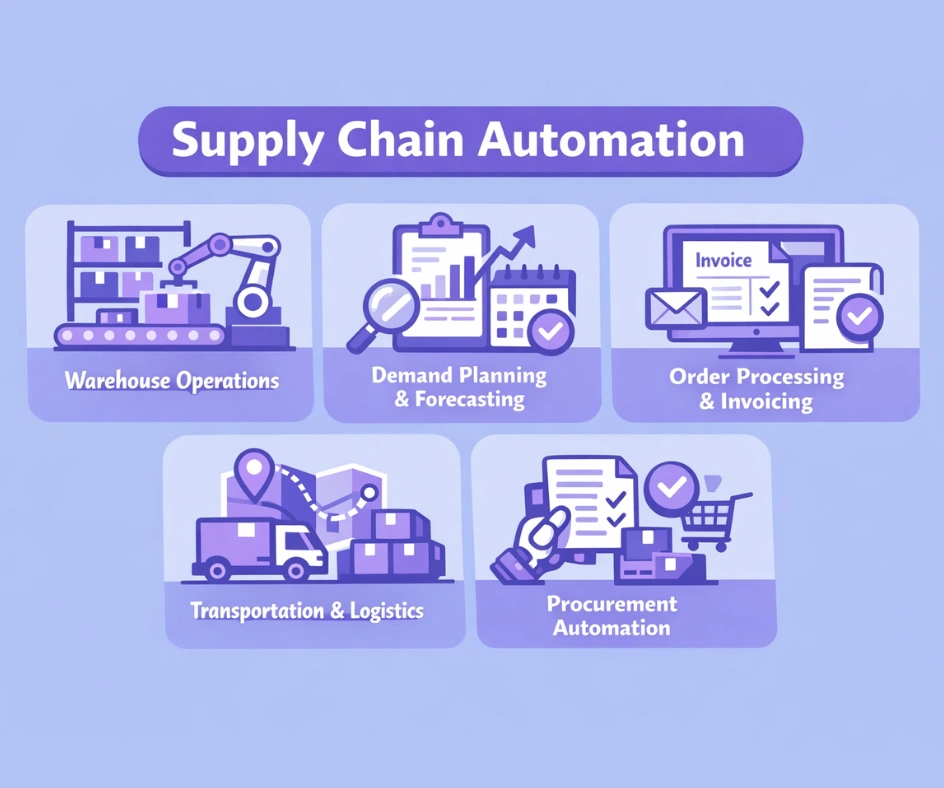

Supply chain automation is about replacing manual, time-consuming tasks with technology that can do the same work faster, cheaper, and with fewer mistakes. This goes far beyond just robots in a warehouse. It covers everything from automated order processing and AI-powered demand planning to self-driving delivery vehicles and smart contract payments.

The need for automation has grown dramatically in recent years. Labor shortages in warehousing and trucking have forced companies to look for alternatives. At the same time, customer expectations for faster delivery and lower prices keep rising. Automation helps businesses meet these demands without proportionally increasing their workforce or costs.

Here are the key areas where supply chain automation is making the biggest difference:

1. Warehouse Operations

Automated guided vehicles (AGVs), robotic picking systems, and smart conveyor belts are transforming warehouses. Companies like Amazon have been pioneers in this space, using thousands of robots to move goods around their fulfillment centers. The result is faster picking, fewer errors, and the ability to handle peak demand without hiring thousands of temporary workers.

2. Demand Planning and Forecasting

AI-driven demand planning tools analyze historical sales data, weather patterns, social media trends, and economic indicators to predict what customers will want and when. Gartner predicts that 70 percent of large organizations will adopt AI-based supply chain forecasting by 2030. This kind of forecasting helps businesses avoid both overstocking (which ties up cash) and understocking (which loses sales).

3. Order Processing and Invoicing

RPA bots can handle order entry, invoice matching, and payment processing without any human involvement. This not only speeds up the process but also eliminates the kind of human errors that cause disputes and delays. Smart contracts on blockchain take this a step further by automatically releasing payments when preset conditions are met, such as when a shipment is confirmed as delivered.

4. Transportation and Logistics

AI-powered route optimization tools calculate the fastest and most fuel-efficient routes for delivery trucks. IoT sensors track vehicle health and alert maintenance teams before breakdowns happen. And in some cases, autonomous vehicles and drones are being tested for last-mile delivery. Real-time transportation monitoring increased by 48 percent in 2024 in the US alone.

5. Procurement Automation

AI-based vendor evaluation systems are changing how companies choose their suppliers. In 2024, more than 13,800 companies deployed these systems globally. They use historical data, performance scores, and risk factors to automatically recommend the best suppliers, removing bias and speeding up the sourcing process.

Recommended Reading:

Supply Chain Risk Control: Preparing for the Unexpected

Supply chain risk control is the process of identifying, assessing, and managing threats that could disrupt the flow of goods and materials. In a world where global disruptions have become the norm rather than the exception, risk management is no longer a nice-to-have. It is a survival skill.

The numbers paint a clear picture. According to the BCI Supply Chain Resilience Report 2024, almost 80 percent of organizations experienced supply chain disruptions in the past twelve months. Supply chain disruptions increased 38 percent year over year in 2024, according to Resilinc. The top causes included factory fires, labor disruptions (up 47 percent year over year), geopolitical risks (up 123 percent), extreme weather events, and cyber attacks.

The financial damage is staggering. McKinsey calculates that within 10 years, supply chain disruptions tally to close to 45 percent of a year’s worth of profits. A single long-term disruption to production can cost companies 30 to 50 percent of a year’s EBITDA. Even a disruption lasting just 30 days can result in losses of 3 to 5 percent of EBITDA.

Here is how digital tools are helping companies manage these risks:

1. Predictive Analytics for Early Warning

AI systems scan news feeds, weather forecasts, geopolitical reports, and supplier data to identify potential disruptions before they happen. In 2024, 43 percent of manufacturers used predictive analytics to assess supplier performance and predict disruption risks. This allows companies to switch suppliers, reroute shipments, or adjust production schedules before a crisis hits.

2. Multi-Tier Supplier Mapping

One of the biggest blind spots in supply chain management is what happens beyond your direct suppliers. The BCI report found that 17.1 percent of respondents now analyze their critical suppliers down to tier 4 and beyond, a significant rise from just 3.7 percent the year before. Digital platforms make this kind of deep mapping possible, revealing hidden dependencies and vulnerabilities.

3. Cybersecurity Defenses

As supply chains become more digital, they also become more vulnerable to cyber attacks. Over 6,900 reported cyberattacks targeted supply chain platforms in 2023, with companies reporting an average of 18 hours of downtime per attack. Businesses are investing in encryption, multi-factor authentication, real-time monitoring, and incident response plans to protect their digital supply chain infrastructure.

4. Diversification and Multi-Sourcing

Digital tools help companies identify alternative suppliers quickly. Instead of relying on a single source for critical materials, businesses can use AI to maintain a database of pre-vetted backup suppliers across different geographies. This proved especially important during the US-China trade tensions of 2024, when tariffs on $300 billion worth of Chinese imports forced many companies to rapidly find new sourcing options.

5. Scenario Planning with Digital Twins

Digital twins allow companies to simulate different disruption scenarios and test their response plans without any real-world risk. What happens if a key port shuts down for two weeks? What if a supplier goes bankrupt? What if demand suddenly spikes by 40 percent? These questions can be answered in hours rather than weeks, giving businesses a major advantage in preparedness.

Real World Examples of Supply Chain Digital Transformation

Theory is great, but what does digital supply chain transformation look like in practice? Here are some examples that show how different companies and industries are using these technologies.

Walmart and Food Traceability: Walmart uses IBM’s Food Trust blockchain to trace the origin of food products. Before blockchain, tracing a bag of mangoes back to its farm took about 7 days. With blockchain, it takes 2.2 seconds. This speed is critical when a contamination issue is discovered, and products need to be pulled from shelves immediately.

Maersk and Digital Shipping: The world’s largest container shipping company partnered with IBM to create TradeLens, a blockchain based shipping platform that digitized the documentation and tracking of millions of containers. While TradeLens was discontinued in 2022 due to industry adoption challenges, it proved that digital transformation in global logistics was not only possible but necessary. Maersk continues to invest heavily in digital tools for its operations.

Amazon and Warehouse Automation: Amazon uses over 750,000 robots across its fulfillment centers, handling tasks from inventory storage to order picking. This level of automation allows Amazon to process orders in hours rather than days, setting the standard for the entire e-commerce industry.

Unilever and Sustainable Sourcing: Unilever uses blockchain and satellite imaging to track the sustainability of its palm oil supply chain. This helps the company prove to regulators and consumers that its products are ethically sourced, avoiding deforestation and exploitative labor practices.

DHL and Predictive Logistics: DHL uses AI and IoT to predict delivery delays, optimize routes, and manage warehouse operations. The company’s use of data analytics has helped it reduce delivery times and improve customer satisfaction across its global network.

Supply Chain Disruptions: Causes, Costs, and Digital Responses

| Disruption Type | Impact / Scale | Digital Solution |

|---|---|---|

| Geopolitical Conflicts | 123% increase in geopolitical risks in 2024 (Resilinc); Red Sea crisis caused 10 to 14-day shipping delays | AI-powered risk monitoring, multi-sourcing platforms, and alternative route planning |

| Cyber Attacks | 6,900+ attacks on supply chain platforms in 2023; 18 hours average downtime per attack | Blockchain data integrity, encryption, real-time threat detection, and incident response automation |

| Extreme Weather | Panama Canal drought caused 32% reduction in transit capacity; hurricanes caused billions in losses | Predictive weather analytics, digital twin simulations, dynamic rerouting tools |

| Labor Disruptions | 47% YoY increase in labor disruptions in 2024; ILA port strike impacted 47,000+ workers | Warehouse robotics, RPA for manual tasks, and AI workforce planning |

| Third Party Failures | 43.6% of organizations experienced disruption from third-party failures in 2024 | Multi-tier supplier mapping, AI-based supplier scoring, diversified vendor databases |

| Trade Restrictions | 3,000+ new global trade restrictions in 2023; US tariffs on $300B in Chinese imports at 25% | Real-time regulatory tracking, compliance automation, and nearshoring analytics |

Advantages vs Challenges: What to Expect from Supply Chain Digital Transformation

Every big shift comes with both rewards and hurdles. Supply chain digital transformation is no different. The good news is that the advantages far outweigh the difficulties, and most challenges have practical solutions. Here is a balanced look at both sides so you can plan your transformation journey with full clarity.

Advantages

1. Faster and Smarter Decision Making

When data flows in real time from every part of the supply chain, leaders can make informed decisions in minutes instead of days. Digital twins alone can increase decision-making speed by up to 90 percent, according to McKinsey. AI-powered analytics remove guesswork from demand planning, route optimization, and supplier selection, replacing it with data-backed insights.

2. Lower Operational Costs

Automation of repetitive tasks like order processing, invoice matching, and inventory counting reduces labor costs and eliminates human errors. Companies using IoT-driven inventory management have reported up to 30 percent reductions in stockouts and waste. AI adoption can cut logistics costs by 15 percent and boost service efficiency by 65 percent across the supply chain.

3. Complete End-to-End Visibility

Digital tools give businesses the ability to track every product, shipment, and transaction across their entire supply chain. This visibility helps them spot bottlenecks early, reroute shipments before delays happen, and give customers accurate delivery updates. Nearly 8 in 10 businesses were implementing end-to-end dashboards for full supply chain visibility in 2023.

4. Stronger Risk Preparedness

Predictive analytics, multi-tier supplier mapping, and digital twin simulations help businesses identify risks before they turn into crises. Companies that embraced digital transformation during the pandemic recovered faster because they had the visibility and agility to adapt in real time.

5. Better Customer Experience

Faster delivery, accurate tracking, fewer stockouts, and transparent sourcing all lead to happier customers. According to a Voxware survey, 65 percent of customers stop shopping with a retailer after two to three late deliveries. Digital supply chains help prevent these situations before they damage customer relationships.

Challenges to Be Aware Of

1. Upfront Costs and Talent Gaps

Deploying AI, IoT, and blockchain systems does require initial investment, and finding people who understand both supply chain operations and digital technology remains difficult. A Gartner survey found that 58 percent of supply chain leaders see rapid tech advancement as a challenge. However, cloud-based subscription models are making advanced tools accessible even to smaller firms without large capital outlays.

2. Legacy System Integration

Many businesses still run on older ERP systems and spreadsheets. Connecting new digital tools with these existing systems needs careful planning and sometimes custom development. The key is to start with pilot projects in high-impact areas rather than trying to overhaul everything at once.

3. Data Security and Interoperability

As supply chains generate more data, protecting it from cyber threats becomes essential. At the same time, different companies in the same supply chain often use different platforms and data formats, making smooth communication a technical challenge. Blockchain technology is helping solve both problems by providing tamper-proof records and shared data environments that all parties can trust.

Recommended Reading:

Steps to Begin Your Supply Chain Digital Transformation

Starting a digital supply chain transformation can feel overwhelming, but it does not have to happen all at once. Here is a practical, step-by-step approach that works for businesses of any size.

1. Assess Your Current State

Before investing in any technology, take a hard look at where you are today. Map out your entire supply chain, from raw material suppliers to end customers. Identify the biggest pain points, whether that is poor visibility, slow order processing, frequent disruptions, or high error rates. This assessment becomes your baseline.

2. Define Clear Goals

Digital transformation without clear goals is just spending money on technology. Decide what you want to achieve. Is it 20 percent faster order fulfillment? 30 percent fewer stockouts? Real-time visibility across all tiers of your supply chain? These specific, measurable goals will guide every decision you make.

3. Start Small with Pilot Projects

Do not try to digitalize everything at once. Pick one high-impact area, maybe it is warehouse automation, demand forecasting, or supplier tracking, and run a pilot project. Test the technology, measure the results, learn from the mistakes, and then scale up based on what works.

4. Invest in Your People

The best technology in the world is useless if your team does not know how to use it. Gartner’s warning about 60 percent of digital efforts failing due to a lack of learning and development investment is worth repeating. Build training programs, hire digital talent, and create a culture that embraces continuous learning.

5. Choose the Right Technology Partners

You do not have to build everything from scratch. Work with experienced technology partners who understand both the technical side and the supply chain side of the equation. The right partner can help you avoid common pitfalls, integrate with your existing systems, and get to value faster.

6. Focus on Data Quality

AI and analytics are only as good as the data they are fed. Make sure your data is clean, consistent, and accessible. This often means investing in data governance, master data management, and integration middleware before or alongside your digital transformation projects.

7. Measure, Learn, and Iterate

Digital transformation is not a one-time project. It is an ongoing process of measurement, learning, and improvement. Set up dashboards to track your key performance indicators, review them regularly, and adjust your approach based on what the data tells you.

The Future of Supply Chain Digital Transformation

The pace of supply chain innovation is only going to accelerate. Here are the trends that will shape the next five to ten years of supply chain management.

Generative AI will become mainstream. While traditional AI has been analyzing data for years, generative AI is opening new possibilities. From automatically writing procurement contracts to generating risk reports to creating optimized production schedules, Gen AI will become a daily tool for supply chain professionals. According to the 2024 KPMG U.S. CEO Outlook, 41 percent of leaders plan to increase their investment in generative AI.

Autonomous supply chains will emerge. A Gartner survey found that 45 percent of supply chains are expected to be mostly autonomous by 2035. This means AI systems will make real-time decisions about sourcing, production, inventory, and delivery with minimal human intervention. Humans will shift from executing tasks to setting strategy and handling exceptions.

Sustainability will drive digitalization. Consumers, regulators, and investors are pushing companies to prove their environmental and social responsibility. Digital tools make this possible by tracking carbon emissions, waste, water usage, and labor practices across the entire supply chain. Blockchain, in particular, enables verifiable sustainability reporting.

Blockchain and IoT convergence will deepen. The combination of IoT sensors (collecting real-time data) and blockchain (storing it immutably) will create supply chains where every product can be traced from origin to destination with complete confidence. This is especially important for industries like pharmaceuticals, food, and luxury goods, where authenticity matters.

Edge computing will speed up decision-making. Instead of sending all data to a central cloud for processing, edge computing processes data locally at the point of collection. This means faster responses to real-time events, which is critical for time-sensitive supply chain decisions.

Quantum computing will enter the picture. While still in its early stages, quantum computing has the potential to solve complex optimization problems that are currently beyond the reach of classical computers. This could transform everything from route optimization to materials science to financial risk modeling.

Blockchain and Smart Contract Implementations in Real World Supply Chains

The following projects show how blockchain architecture, smart contracts, and decentralized infrastructure are already being applied in supply chain management, logistics tracking, and automated procurement workflows. Each implementation uses the same distributed ledger principles discussed throughout this blog, from IoT integration and smart contract automation to transparent data sharing and tamper-proof record keeping.

📦

Spectrum Finance: Cross-Chain Blockchain Solutions

Built a blockchain platform enabling cross-chain transactions, native asset swaps, and decentralized operations without intermediaries. The system supports high transaction volumes, multi-network compatibility, and community-driven governance, reflecting the same transparency and automation principles that supply chain platforms use for multi-party data sharing and automated settlement workflows.

🔗

Everscale Network: High Throughput Blockchain Ecosystem

Developed a highly performant blockchain network capable of processing over 100,000 transactions per second through sharding technology. This kind of high-throughput infrastructure is exactly what large-scale supply chains need for real-time tracking, automated payment processing, and handling millions of IoT data points from sensors across global logistics networks.

Transform Your Supply Chain with Blockchain and Digital Solutions:

We bring years of blockchain and digital transformation expertise to supply chain management. Our team handles everything from smart contract automation and IoT integration to multi-tier visibility platforms, ensuring your supply chain is built for speed, transparency, and resilience. Whether you need a blockchain-powered traceability system or an AI-driven logistics platform, we deliver solutions that work.

Conclusion

Supply chain digital transformation is not a buzzword or a trend that will fade away. It is a fundamental shift in how businesses operate, compete, and survive in a world of constant disruption. The data makes this clear. Markets for AI, IoT, blockchain, visibility software, and cloud solutions in the supply chain space are all growing at double-digit rates. Companies that have embraced these technologies are recovering from disruptions faster, serving customers better, and operating more efficiently than those still stuck with manual processes.

But transformation is not just about technology. It is about people, processes, and culture. It is about training your team, choosing the right partners, starting with small pilots, and scaling what works. It is about investing in data quality, building cybersecurity defenses, and staying agile as new technologies like generative AI and quantum computing enter the picture.

The businesses that will lead in the next decade are the ones that treat their supply chain not as a cost center to be minimized, but as a strategic asset to be continuously improved through digital innovation. The tools are available. The data support the investment. The only question is whether you will take the first step today or wait until your competitors have already crossed the finish line.

Frequently Asked Question

Supply chain digital transformation is the process of using modern technologies like AI, IoT, blockchain, and cloud computing to replace manual, paper-based supply chain operations with connected digital systems that share data in real time and enable faster, smarter decision-making.

Supply chain visibility allows businesses to track every product, shipment, and transaction across their entire supply chain in real time. Without it, companies cannot identify bottlenecks, predict delays, or respond quickly to disruptions. Studies show that 45 percent of companies have no visibility beyond their first-tier suppliers.

AI improves supply chains by analyzing large volumes of data to forecast demand, optimize delivery routes, evaluate supplier performance, detect fraud, and automate repetitive tasks. Companies using AI in supply chains have reported both cost reductions and revenue increases in the business units that deploy the technology.

Blockchain creates a tamper-proof, shared digital ledger that records every transaction in the supply chain. It is used for product traceability, fraud prevention, smart contract automation, and verified sustainability reporting. Companies like Walmart and Nestle use blockchain to trace food products back to their origin in seconds.

The biggest challenges include high initial costs, talent shortages, integrating new tools with legacy systems, cybersecurity risks, data quality issues, and resistance to change among employees and partners. Gartner warns that 60 percent of digital adoption efforts will fail by 2028 without proper investment in training.

Small businesses should start by assessing their current supply chain pain points, setting clear and measurable goals, running small pilot projects in high-impact areas, and using cloud-based tools that do not require large upfront investment. Working with experienced technology partners can also help avoid costly mistakes and speed up time to value.

Reviewed & Edited By

Aman Vaths

Founder of Nadcab Labs

Aman Vaths is the Founder & CTO of Nadcab Labs, a global digital engineering company delivering enterprise-grade solutions across AI, Web3, Blockchain, Big Data, Cloud, Cybersecurity, and Modern Application Development. With deep technical leadership and product innovation experience, Aman has positioned Nadcab Labs as one of the most advanced engineering companies driving the next era of intelligent, secure, and scalable software systems. Under his leadership, Nadcab Labs has built 2,000+ global projects across sectors including fintech, banking, healthcare, real estate, logistics, gaming, manufacturing, and next-generation DePIN networks. Aman’s strength lies in architecting high-performance systems, end-to-end platform engineering, and designing enterprise solutions that operate at global scale.