Key Takeaways

- The global blockchain for supply chain traceability market was valued at USD 2.89 billion in 2024 and is expected to reach USD 44.3 billion by 2034, growing at a CAGR of 31.40% during the forecast period

- Walmart reduced its mango traceback time from 7 days to just 2.2 seconds after implementing IBM Food Trust blockchain, and by 2020, over 200 leafy green suppliers had joined the system.

[1] - Global trade in counterfeit goods reached USD 1.023 trillion in 2023 and is projected to hit USD 1.79 trillion by 2030, making anti-counterfeiting through blockchain traceability a growing priority.

[2] - De Beers has registered over 3 million diamonds on its Tracr blockchain platform since 2022, now providing single country of origin data for all De Beers-sourced rough diamonds over one carat.

[3] - Product traceability accounted for 38% of all blockchain supply chain revenue in 2024, while smart contracts are expanding at a 52.65% CAGR through 2030.

[4] - The World Health Organisation (WHO) estimates that 1 in 10 medical products in low and middle-income countries is substandard or falsified, driving blockchain adoption in pharmaceutical supply chains.

[5]

When you buy a bottle of medicine from a pharmacy, how do you know it is real? When a grocery store sells fresh vegetables, how can the store prove where those vegetables were grown? And when a fashion brand sells an expensive bag, how does the buyer confirm it is not a copy?

These are real problems that affect billions of people across the world. From food contamination scares to fake luxury goods, supply chains today are broken in many ways. Products move through dozens of hands before reaching the final buyer. At each step, there is a chance for mistakes, fraud, or manipulation. Traditional tracking systems depend on paper records, isolated databases, and trust between parties. But when supply chains stretch across multiple countries, keeping track of everything becomes very hard.

This is where blockchain for supply chain traceability steps in, offering modern supply chain solutions that improve transparency and accountability. By using a shared, tamper-proof digital ledger that every participant can access, blockchain creates a single source of truth for every product’s journey. No one person or company controls the data. Once something is recorded, it cannot be changed or deleted. This kind of transparency and trust is something traditional systems have struggled to deliver for decades.

In this blog, we will break down what blockchain-based supply chain traceability actually means, how it works step by step, where it is being used today with real examples, and why it matters for businesses and consumers alike.

What is Blockchain-Based Supply Chain Traceability?

Blockchain-based supply chain traceability is a way of recording, verifying, and tracking every movement of a product across its lifecycle using a secure digital ledger. Think of it like a notebook that many people share, but no one can erase or change what has already been written in it.

Every time a product is manufactured, tested, packed, shipped, stored, or delivered, that event gets recorded as a permanent entry on the blockchain ledger. This entry becomes an immutable record, which means it cannot be changed, copied, or deleted by anyone. Every participant in the supply chain, whether it is a farmer, a manufacturer, a shipping company, a distributor, or a retailer, can see the same verified information.

Unlike old traceability systems that depend on one company to keep the records correct, blockchain does not need a single authority. Instead, the data is verified by a network of computers using cryptographic proofs. This means that the product authenticity and transparency are enforced by the technology itself, not by any one person’s promise.

For example, if a batch of milk is contaminated and reaches a supermarket shelf, a blockchain-based system can identify exactly which farm it came from, which processing plant handled it, and which trucks transported it, all within seconds. Without blockchain, this same process could take days or even weeks.

Why Do Supply Chains Need Blockchain?

Modern supply chains are incredibly complex. A single product might pass through 10 to 15 different companies across 5 or more countries before it reaches the buyer. At each step, different systems, formats, and records are used. This creates information gaps that can be exploited.

Here are some of the biggest problems in today’s supply chains that blockchain traceability addresses:

1. Counterfeiting and Fake Products

Counterfeit goods are a massive global problem. According to Corsearch research, global trade in counterfeit goods reached USD 1.023 trillion in 2023 and is projected to grow to USD 1.79 trillion by 2030. That means roughly 1 in every 20 dollars spent on products globally could be going to fakes. Blockchain traceability directly fights this by giving every product a verified, traceable history that counterfeits cannot replicate.

2. Lack of Transparency

In many supply chains, companies only know about the parties directly before and after them. A retailer might know its distributor but has no idea about the farmer who grew the raw ingredients. This “one step forward, one step back” model leaves huge blind spots. Blockchain provides end-to-end visibility, allowing every participant to see the complete journey of a product.

3. Slow Recall Processes

When a food safety issue or product defect is discovered, companies often struggle to identify exactly which batches are affected. Walmart’s experience before blockchain showed this clearly: tracing the origin of a bag of sliced mangoes took nearly 7 days. With blockchain, this was reduced to 2.2 seconds. The difference in speed can literally save lives.

4. Falsified Documentation

Paper certificates and digital documents stored in isolated databases can be forged or altered. Blockchain solves this by making every record tamper-proof. Once data is entered and validated by the network, it becomes a permanent part of the chain.

5. Regulatory Pressure

Governments around the world are tightening rules around supply chain traceability. In the United States, the FDA’s FSMA Rule 204 now requires companies handling high-risk foods to maintain detailed tracking records and provide traceability data within 24 hours upon request. Similar rules exist in the European Union with the Farm to Fork strategy. Blockchain makes meeting these requirements much easier.

Recommended Reading:

How Does Blockchain Traceability Work Step by Step?

Understanding blockchain-based supply chain traceability becomes easier when you look at how it works in a real supply chain. Here is a simple breakdown of the process from start to finish:

1. Assigning a Unique Digital Identity (UID)

Every product unit or batch is given a unique digital identity. This can be a QR code, NFC chip, or RFID tag attached to the product. This identity acts like a digital passport that follows the product everywhere it goes.

2. Recording Supply Chain Events

Every action that happens to the product creates a digital event. Manufacturing, quality testing, packaging, loading onto a truck, arriving at a warehouse, temperature checks during transport, customs clearance, and delivery to the store are all examples of events that get recorded.

3. Writing Events to the Blockchain Ledger

Each digital event is written to the blockchain ledger as a new block. This block is linked to the previous one using cryptographic hashing, creating a chain of records that cannot be broken or changed. This is what makes the record immutable.

4. Cryptographic Verification

Before a new block is added, the network of participants verifies the transaction using cryptographic proofs. This means that no single party can add false information. The distributed nature of the network ensures that tracking and authentication are maintained without needing a central authority.

5. Consumer and Brand Access

At the end of the chain, brands and consumers can scan a QR code or use an app to view the entire journey of the product. They can see where raw materials came from, how the product was made, when it was shipped, and at what temperature it was stored. This is what real-time tracking looks like in practice.

Key Benefits of Blockchain for Supply Chain Traceability

Blockchain offers several clear advantages over traditional supply chain management systems. Let us go through each one in detail.

1. End-to-End Visibility Across the Entire Chain

One of the biggest advantages of blockchain is that it gives every participant in the supply chain access to the same data in real time. Manufacturers, distributors, retailers, regulators, and even consumers can all see where a product has been, what has happened to it, and where it is right now. This kind of end-to-end visibility removes information silos and builds trust between parties that may not know each other.

2. Stronger Anti-Counterfeiting Protection

Since every product has a verified, traceable history on the blockchain, it becomes extremely difficult for counterfeit goods to enter the supply chain unnoticed. The anti-counterfeiting power of blockchain comes from the fact that fake products simply cannot have a matching blockchain history. Brands can instantly identify whether a product is genuine or not by checking its blockchain record.

3. Faster and More Targeted Recalls

When a product defect or contamination is found, blockchain allows companies to pinpoint exactly which batches are affected. Instead of pulling all products from the market (which is expensive and wasteful), companies can issue targeted recalls for only the specific units that have a problem. This saves money and protects more consumers at the same time.

4. Regulatory Compliance Support

With regulations like the FDA’s DSCSA for pharmaceuticals and FSMA Rule 204 for food safety, companies need detailed, accurate, and accessible records of their supply chains. Blockchain creates the kind of immutable record that regulators require. Compliance support becomes much simpler because the data is already organised, verified, and ready to share within the 24-hour window that many regulations demand.

5. Smart Contracts for Automation

Smart contracts are programs stored on the blockchain that automatically execute when certain conditions are met. For example, a smart contract could automatically release payment to a supplier when a shipment is confirmed as received and verified. According to industry research, smart contracts in supply chains help reduce invoice processing cycle times by up to 90% in production environments. This removes the need for manual paperwork and speeds up operations.

6. Greater Consumer Trust

Today’s consumers care more than ever about where their products come from. They want to know if their food is organic, if their clothes are made ethically, and if their medicines are genuine. Blockchain gives brands a way to prove all of this with verified data, not just marketing claims. When customers can scan a product and see its full history, trust increases dramatically.

Blockchain Traceability vs Traditional Traceability

| Feature | Traditional Traceability | Blockchain Based Traceability |

|---|---|---|

| Data Storage | Centralised databases controlled by individual companies | Distributed ledger shared across all participants |

| Data Integrity | Records can be edited or deleted by administrators | Immutable records that cannot be altered once written |

| Transparency | Limited to one step forward, one step back visibility | Full end-to-end visibility for all authorised parties |

| Traceback Speed | It can take days or weeks to trace a product’s origin | Can trace a product’s origin in seconds |

| Trust Model | Depends on trust between individual parties | Trust is built into the technology through cryptographic proofs |

| Automation | Manual processes for verification and payments | Smart contracts automate verification, payment, and compliance |

| Anti-Counterfeiting | Relies on physical certificates that can be forged | Digital identity verified through blockchain makes forgery nearly impossible |

Real World Examples of Blockchain Supply Chain Traceability

Blockchain traceability is not just a theory. Major companies across the world are already using it to solve real supply chain problems. Let us look at some of the most important implementations.

1. Walmart and IBM Food Trust

Walmart’s partnership with IBM is one of the most well-known examples of blockchain in supply chains. Using Hyperledger Fabric, they built the IBM Food Trust platform to track food products from farm to shelf. Before blockchain, tracing the origin of a package of sliced mangoes took Walmart’s team 6 days, 18 hours, and 26 minutes. After implementing blockchain, this dropped to just 2.2 seconds. By 2020, Walmart made this system required for all its leafy green suppliers. Over 300 suppliers and buyers have since joined the IBM Food Trust network, covering millions of packaged food products on store shelves.

2. De Beers and the Tracr Platform

The diamond industry has long struggled with conflict diamonds and fake stones. De Beers launched its Tracr blockchain platform in 2018 to address this. Each diamond is given a unique digital identity that captures critical details like carat weight, colour, clarity, and cut. As of 2025, Tracr has registered over 3 million diamonds at source, and De Beers now registers more than two-thirds of its global production by value on the platform. The platform provides single country of origin data for all De Beers sourced diamonds over one carat, giving consumers verifiable proof of where their diamond came from. Tracr has been featured three times on the Forbes Blockchain 50 list.

3. VeChain in Food, Luxury, and Pharmaceuticals

VeChain is a blockchain platform specifically designed for supply chain management. It combines blockchain with IoT devices like QR codes, NFC chips, and RFID tags to create traceable digital identities for physical products. Walmart China partnered with VeChain to launch the Walmart China Blockchain Traceability Platform, tracking over 20 product categories. Luxury brands use VeChain to verify product authenticity and fight counterfeiting. In pharmaceuticals, VeChain’s technology supports cold chain monitoring and regulatory compliance for drug authenticity.

4. MediLedger for Pharmaceutical DSCSA Compliance

In 2019, IBM, KPMG, Merck, and Walmart came together for an FDA pilot program to test blockchain’s ability to meet the Drug Supply Chain Security Act (DSCSA) requirements. The MediLedger project demonstrated that a blockchain-based system can handle package-level drug tracing and verification. This is especially important given that the WHO estimates 1 in 10 medical products in low and middle-income countries is substandard or falsified.

Recommended Reading:

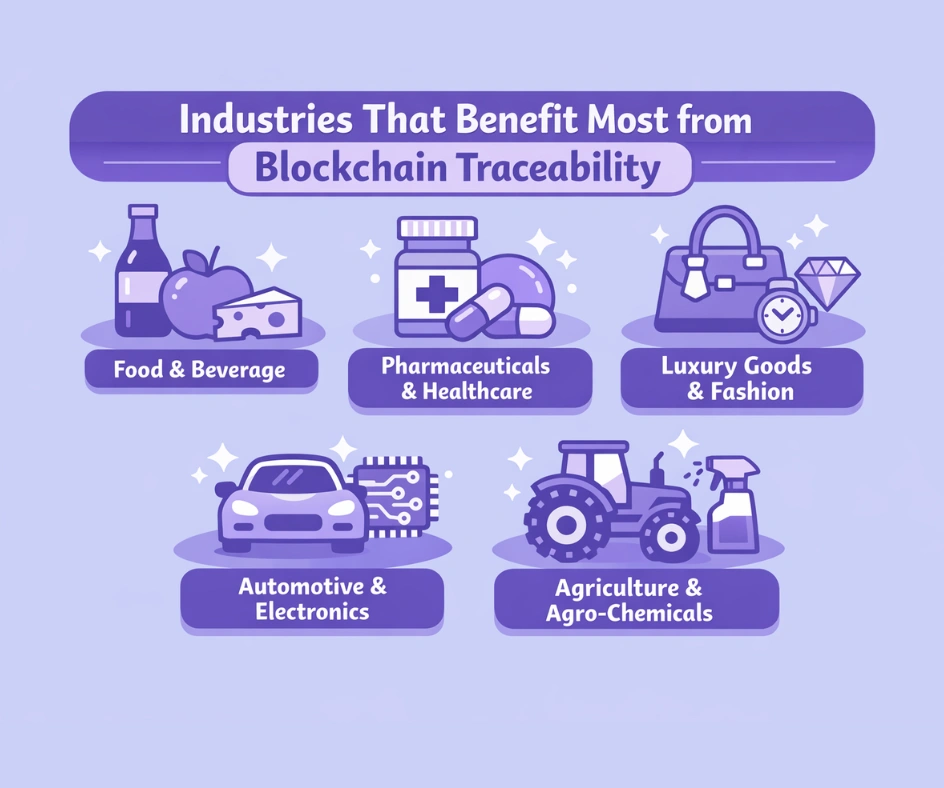

Industries That Benefit Most from Blockchain Traceability

Blockchain for supply chain traceability is not limited to one industry. Its ability to create tamper-proof records and end-to-end visibility makes it useful across many sectors. Here are the key industries where blockchain traceability is making the biggest impact.

1. Food and Beverage

The food and beverage segment held over 23% of the blockchain supply chain traceability market in 2024. Consumers are increasingly concerned about where their food comes from and whether it is safe. Blockchain allows companies to track every ingredient from the farm to the table, verify certifications like organic or fair trade, and respond to contamination events within seconds instead of days. The FDA’s FSMA Rule 204 is pushing more food companies to adopt blockchain-based traceability for compliance support.

2. Pharmaceuticals and Healthcare

The pharmaceutical industry faces major challenges with counterfeit drugs, especially in developing countries. The DSCSA in the United States requires electronic tracking of prescription drugs at the package level. Blockchain provides the kind of immutable record and real-time tracking that this regulation demands. Companies can track drugs from the manufacturing plant to the pharmacy, ensuring every product in the chain is genuine.

3. Luxury Goods and Fashion

Luxury brands lose billions every year to counterfeiting. Blockchain traceability allows brands to create a digital certificate for every product that proves its authenticity. Consumers can scan a tag on their luxury item and verify its origin, manufacturing details, and ownership history. This technology is already being used by companies like De Beers (for diamonds) and VeChain (for fashion and luxury goods).

4. Automotive and Electronics

In the automotive industry, counterfeit parts can cause serious safety issues. Blockchain helps track every component from the supplier to the assembly line, ensuring that only genuine, tested parts are used. In electronics, it helps verify that conflict-free minerals are being used and that components are coming from approved sources.

5. Agriculture and Agro-Chemicals

Farmers, distributors, and retailers benefit from blockchain by being able to prove the origin of crops, track pesticide usage, and verify that products meet safety standards. This is especially important for export markets where buyers demand proof of quality and safety.

Blockchain Supply Chain Traceability Market by Industry

| Industry Segment | Market Share in 2024 | Key Use Cases |

|---|---|---|

| Food and Beverage | Over 23% | Farm to table tracking, contamination response, and organic certification verification |

| Retail and E-Commerce | Approx. 23.9% | Product authenticity, ethical sourcing proof, and returns management |

| Pharmaceuticals | Growing at the fastest rate | Drug serialisation, DSCSA compliance, cold chain monitoring |

| Luxury Goods | Significant adoption | Anti-counterfeiting, provenance verification, and digital certificates of authenticity |

| Manufacturing | Growing at 76.26% CAGR | Parts traceability, quality control, and supplier verification |

| Automotive | Steady growth | Component tracking, recall management, safety compliance |

The Role of Smart Contracts in Supply Chain Traceability

Smart contracts are one of the most powerful features of blockchain technology when applied to supply chains. A smart contract is basically a program that lives on the blockchain and automatically runs when specific conditions are met. No human intervention is needed once the contract is set up.

In a supply chain, smart contracts can handle many tasks that currently require manual work, paperwork, and trust between parties. Here are some practical examples of how they work:

When a shipment arrives at a warehouse and is scanned as received, the smart contract can automatically trigger payment to the shipper. There is no waiting for invoices, no back-and-forth emails, and no delays. The transaction happens instantly because the condition (delivery confirmed) has been met.

Smart contracts can also enforce quality standards. If a temperature sensor on a pharmaceutical shipment records that the drugs were exposed to heat above the safe limit, the smart contract can automatically flag the batch as non-compliant and prevent it from being delivered to pharmacies.

For regulatory compliance, smart contracts can automatically generate audit reports every time a product passes through a critical tracking point. This means companies always have up-to-date compliance records without any manual data entry.

According to research from Mordor Intelligence, smart contracts in the blockchain supply chain market are expanding at a CAGR of 52.65% through 2030, making them the fastest-growing application segment. This growth reflects how much value automation brings to supply chain operations.

How IoT and Blockchain Work Together for Better Traceability

Blockchain by itself records data, but it still needs a way to collect data from the physical world. This is where the Internet of Things (IoT) comes in. IoT devices like temperature sensors, GPS trackers, RFID tags, NFC chips, and barcode scanners collect real-world data and feed it directly into the blockchain ledger.

For example, in a cold chain for vaccines, IoT temperature sensors continuously monitor the storage conditions. Every reading is automatically recorded on the blockchain, creating an unbroken, tamper-proof record of the vaccine’s temperature history. If at any point the temperature goes outside the safe range, the system can instantly flag the issue.

GPS trackers attached to shipping containers record the exact location of goods throughout their journey. This data, when stored on the blockchain, provides verifiable proof of where a product has been at every moment. Combined with timestamps, this creates a complete picture of the product’s journey that cannot be disputed.

The combination of IoT and blockchain is particularly powerful for industries like pharmaceuticals, food, and luxury goods, where conditions during transport directly affect product quality and authenticity. Major platforms like VeChain already integrate QR codes, NFC chips, and RFID chips with their blockchain to create this kind of end-to-end tracking and authentication system.

Recommended Reading:

Regulatory Frameworks Driving Blockchain Adoption

One of the biggest forces pushing companies toward blockchain for supply chain traceability is government regulation. Around the world, lawmakers are tightening rules around product tracking, food safety, and drug authentication. Here are the most important regulations that are driving adoption:

1. FDA’s FSMA Rule 204 (United States)

The Food Safety Modernisation Act (FSMA) Rule 204 requires companies handling high-risk foods to maintain enhanced traceability records. Businesses must assign unique Traceability Lot Codes (TLCs) and provide data to the FDA within 24 hours upon request. The FDA has recognised blockchain as a breakthrough traceability technology, and many companies are turning to blockchain-based systems to meet these requirements.

2. Drug Supply Chain Security Act (DSCSA)

The DSCSA, enacted in 2013, set a 10-year plan to build an electronic system for tracking prescription drugs at the package level across the U.S. supply chain. Full enforcement began in 2023, and blockchain has emerged as a leading technology to achieve the required interoperability. The MediLedger project demonstrated through an FDA pilot that blockchain can handle DSCSA compliance at scale.

3. EU Farm to Fork Strategy

The European Union’s Farm to Fork strategy promotes traceability technologies to hold food supply chains accountable. This regulation, combined with the EU’s Corporate Sustainability Reporting Directive, is pushing European companies to adopt blockchain for verifying sustainable sourcing and labour practices.

4. G7 Diamond Protocol

Following the G7’s ban on Russian diamond imports in 2024, diamond traceability has become even more important. De Beers’ Tracr platform and its collaboration with Sarine Technologies are directly aligned with these requirements, using blockchain to verify a diamond’s origin as it crosses international borders.

Challenges of Implementing Blockchain in Supply Chains

While blockchain traceability offers many advantages, it is important to understand the challenges that companies face when implementing it. Being aware of these challenges helps businesses plan better and set realistic expectations.

1. High Initial Investment

Setting up a blockchain-based traceability system requires investment in technology, infrastructure, and training. For smaller companies, this upfront cost can be a barrier. However, subscription-based cloud platforms are now available that offer low-code solutions, making it more affordable for small and medium enterprises.

2. Interoperability Between Different Blockchains

One of the biggest technical hurdles is making different blockchain systems work together. A food company might use one blockchain platform while its supplier uses another. These gaps in interoperability add integration costs and slow down deployment.

3. Supplier Onboarding

Blockchain traceability only works if all parties in the supply chain participate. Convincing small farmers, local manufacturers, or traditional distributors to adopt new technology can be difficult. Training and support are essential to get everyone on board.

4. Data Privacy Concerns

While transparency is a key benefit of blockchain, some companies worry about sharing too much business information. Permissioned blockchains (where access is controlled) help address this by allowing companies to share data only with the parties they choose.

5. Scalability

Processing millions of transactions across a global supply chain requires a blockchain network that can handle high volumes. While platforms like VeChainThor and Hyperledger Fabric have been designed with enterprise use in mind, scalability remains an area of active development and improvement.

Blockchain-Based Supply Chain Implementations in the Real World

The following projects show how blockchain architecture is already being used across logistics, traceability, and enterprise operations. Each implementation reflects the same distributed ledger principles discussed throughout this article, from smart contract automation and product tracking to transparent record keeping and multi-party verification.

🔗

Everscale: High-Performance Blockchain Ecosystem

Built a high-throughput blockchain network using sharding and dynamic workload distribution, enabling over 100,000 transactions per second. The Everscale ecosystem supports decentralised applications across finance, logistics, and supply chain operations, offering the kind of enterprise-grade infrastructure needed for real-time product tracking at scale.

⛓️

MerkleScan: Blockchain Explorer for Transparent Verification

Developed a blockchain explorer that provides real-time insights into transactions, blocks, and wallet activities. MerkleScan enables transparent verification of on-chain data, showing detailed interactions with smart contracts, including creation and execution results, essential for auditing and traceability verification in enterprise supply chain systems.

Build Your Blockchain Supply Chain Traceability Solution:

We bring 8+ years of blockchain development expertise to supply chain traceability solutions. Our team handles everything from smart contract creation to IoT integration and distributed ledger deployment, ensuring your system delivers end-to-end visibility, compliance support, and real-time product tracking. Whether you need food traceability, pharmaceutical tracking, or luxury goods authentication, we build solutions that work.

Conclusion

Supply chains today are more complex and more global than ever before. Products travel through multiple countries, pass through dozens of hands, and go through countless processes before they reach the final buyer. In this kind of environment, the old ways of tracking and verifying products simply do not work well enough. Paper records get lost. Databases get hacked. Certificates get forged. And consumers are left without any real way to know whether what they are buying is genuine, safe, or ethically sourced.

Blockchain for supply chain traceability changes this by creating a shared, tamper-proof record of every event in a product’s journey. From the raw material stage to the final sale, every step is recorded on a secure digital ledger that no single party controls and no one can alter. This creates a level of transparency and trust that was simply not possible before.

The numbers tell the story clearly. The blockchain supply chain traceability market was valued at USD 2.89 billion in 2024 and is expected to reach USD 44.3 billion by 2034. Walmart reduced traceback times from 7 days to 2.2 seconds. De Beers has registered over 3 million diamonds on its blockchain platform. The FDA is recognising blockchain as a breakthrough technology for food safety. And smart contracts are automating payments, compliance checks, and quality controls across industries.

Whether you are in food and beverage, pharmaceuticals, luxury goods, automotive, or any other industry with a complex supply chain, blockchain traceability offers a proven way to build trust, meet regulations, fight counterfeiting, and give your customers the transparency they demand. The technology is here, the results are real, and the companies that adopt it now will be the ones leading their industries in the coming decade.

Frequently Asked Questions

Blockchain supply chain traceability is the use of a distributed, tamper-proof digital ledger to record and verify every step of a product’s journey through the supply chain. It creates an immutable record from raw material sourcing to final delivery, giving all participants and consumers access to verified product history.

Blockchain assigns a unique digital identity to every product and records its complete journey. Since these records are immutable and verified by the network, counterfeit products cannot replicate a genuine blockchain history. Brands and consumers can instantly check product authenticity by scanning a QR code or NFC tag.

Major industries include food and beverage, pharmaceuticals, luxury goods, fashion, automotive, electronics, agriculture, and mining. Any industry where product authenticity, safety, or ethical sourcing is important can benefit from blockchain traceability.

Smart contracts automate key processes like payments, compliance checks, and quality verification. When a predefined condition is met, the smart contract executes automatically. This eliminates manual paperwork, reduces delays, and ensures that all parties follow the agreed-upon rules without needing a central authority.

The cost depends on the complexity of the supply chain and the features needed. While large enterprise deployments can require significant investment, cloud-based blockchain platforms now offer affordable options for small and medium businesses. Subscription models and low-code solutions have made adoption more accessible.

Regulations like the FDA’s FSMA Rule 204 require detailed product tracking and the ability to provide traceability data within 24 hours. Blockchain creates the kind of organised, verified, and immutable records that regulators need. It automates record keeping at every critical tracking point, making compliance faster and more accurate.

Reviewed & Edited By

Aman Vaths

Founder of Nadcab Labs

Aman Vaths is the Founder & CTO of Nadcab Labs, a global digital engineering company delivering enterprise-grade solutions across AI, Web3, Blockchain, Big Data, Cloud, Cybersecurity, and Modern Application Development. With deep technical leadership and product innovation experience, Aman has positioned Nadcab Labs as one of the most advanced engineering companies driving the next era of intelligent, secure, and scalable software systems. Under his leadership, Nadcab Labs has built 2,000+ global projects across sectors including fintech, banking, healthcare, real estate, logistics, gaming, manufacturing, and next-generation DePIN networks. Aman’s strength lies in architecting high-performance systems, end-to-end platform engineering, and designing enterprise solutions that operate at global scale.