Key Takeaways

- The global AI in supply chain market was valued at USD 7.15 billion in 2024 and is expected to reach approximately USD 192.51 billion by 2034, growing at a CAGR of 39 per cent

- According to McKinsey, AI-powered forecasting can reduce errors by 30 to 50 per cent in supply chain networks, leading to a 65 per cent reduction in lost sales due to out-of-stock situations.

[1] - Gartner predicts that 70 per cent of large organisations will adopt AI-based supply chain forecasting to predict future demand by 2030, replacing traditional statistical methods.

[2] - The demand forecasting segment accounts for the largest share of 25.2 per cent in the AI in supply chain market, driven by the need for accuracy and resilience in supply chain operations

- Walmart uses a multi-horizon recurrent neural network built entirely in-house to predict demand across multiple time horizons, helping the retailer plan inventory levels more accurately and reduce excess stock in warehouses.

[3] - AI-driven forecasting helps reduce warehousing costs by 5 to 10 per cent and administration costs by 25 to 40 per cent through better planning and resource allocation across supply chains.

[4] - About 45 per cent of companies have already incorporated machine learning into their demand forecasting processes, and this number continues to grow as businesses look for improved accuracy

Every business that makes, ships, or sells products knows this problem very well. You either have too much stock sitting in your warehouse or too little on your shelves when customers actually want to buy. For decades, companies have tried to solve this puzzle using spreadsheets, historical sales data, and a good amount of guesswork. But the world has changed. Customer behaviour shifts overnight. New trends pop up on social media. Weather events, political changes, and global disruptions throw off even the best predictions. Traditional methods of demand forecasting simply cannot keep up anymore.

This is where artificial intelligence steps in. AI demand forecasting in the supply chain is not just a buzzword. It is a real, working technology that some of the biggest companies on the planet are already using to stay ahead. From Walmart to Amazon, businesses are replacing old forecasting models with machine learning algorithms that can process thousands of data points in real time, learn from past mistakes, and make predictions that are far more accurate than anything a human analyst could do alone. That is why AI-driven forecasting is now becoming one of the most valuable supply chain solutions for companies that want better planning, faster decisions, and fewer inventory surprises.

In this blog, we will take a deep look at how AI is transforming demand forecasting in supply chain operations. We will cover the technology behind it, look at real-world examples, explore the numbers and data that show its impact, and understand what it means for businesses of all sizes. Whether you run a small online store or manage supply chains for a large corporation, this guide will help you understand why AI-powered demand forecasting is becoming a must-have tool in modern supply chain management.

What Is AI Demand Forecasting in Supply Chain?

Before we get into the details, let us first understand what demand forecasting actually means. In simple terms, demand forecasting is the process of predicting how much of a product customers will want to buy in the future. Every business needs this information to decide how much to produce, how much raw material to order, how many workers to schedule, and how much warehouse space to keep ready.

Traditional demand forecasting relies mostly on historical sales data. Analysts look at what sold last year during a particular season and use that as the basis for this year’s predictions. They might add a few adjustments based on known events or promotions. But this approach has serious limits. It cannot account for sudden changes in consumer behaviour, unexpected weather patterns, viral social media trends, or supply disruptions happening thousands of miles away.

AI demand forecasting changes this completely. Instead of looking at just one or two data sources, AI systems can analyse hundreds of different inputs at the same time. These include historical sales, weather data, social media activity, competitor pricing, economic indicators, news events, search engine trends, and much more. Machine learning models find patterns in all this data that humans would never notice on their own. And these models keep getting better over time because they learn from every new piece of data they receive.

The result is forecasting that is faster, more detailed, and significantly more accurate. According to McKinsey, AI-driven forecasting can reduce errors by 30 to 50 per cent in supply chain networks. That kind of improvement does not just save money. It can completely change how a business operates.

The Market for AI in Supply Chain Is Growing Fast

The numbers tell a clear story about how quickly businesses are adopting AI for their supply chains. The global AI in supply chain market was valued at USD 7.15 billion in 2024. By 2034, it is expected to reach approximately USD 192.51 billion, growing at a compound annual growth rate of 39 per cent. This is not slow, steady growth. This is a massive surge that shows how seriously businesses are taking this technology.

Within this market, the demand forecasting segment holds the largest share at 25.2 per cent. This makes sense because forecasting sits at the heart of every supply chain decision. If you can predict demand correctly, everything else falls into place: production planning, inventory management, logistics, and even customer satisfaction.

North America leads the charge, holding 39 per cent of the market in 2024. The region is home to major technology companies and has a strong focus on operational efficiency. But Asia Pacific is not far behind. It is expected to grow at the highest rate of 42.5 per cent during the forecast period, driven by countries like China, India, Japan, and South Korea that are major manufacturing and logistics hubs.

These numbers point to a simple truth. AI forecasting for the supply chain is not a future technology. It is here right now, and the companies that adopt it early are gaining a serious advantage over those that stick with older methods.

Recommended Reading:

Supply Chain Digital Transformation: Visibility, Automation & Risk Control

How Does AI-Powered Demand Forecasting Work?

Understanding the technology behind AI demand forecasting in the supply chain does not require a computer science degree. At its core, the process follows a logical flow that any business person can understand. Here is how it works, broken down into clear steps.

1. Data Collection from Multiple Sources

The first step is gathering data. Unlike traditional methods that rely on sales history alone, AI systems pull data from a wide range of sources. These include point of sale records, online transaction data, weather forecasts, social media conversations, search engine trends, economic reports, competitor pricing data, and even satellite imagery in some cases. The more data the system has, the better its predictions become.

2. Data Cleaning and Preparation

Raw data is messy. It often contains errors, duplicates, missing values, and inconsistencies. Before any AI model can use this data, it needs to be cleaned and organized. This step is crucial because the quality of the data directly affects the quality of the forecast. As the saying goes, garbage in, garbage out. AI tools use automated processes to handle much of this cleaning, but human oversight is still important to catch unusual problems.

3. Pattern Recognition Through Machine Learning

Once the data is ready, machine learning algorithms go to work. These algorithms look at the data from many different angles to find patterns, correlations, and relationships that humans would miss. For example, an AI system might discover that umbrella sales in a particular region spike not just when it rains, but two days before rain is forecast, because people see weather warnings on their phones and go shopping early. This kind of subtle pattern is nearly impossible to spot with traditional analysis.

4. Model Training and Testing

The AI model is trained on historical data to learn what happened in the past. Then it is tested against known outcomes to see how accurate its predictions are. This training process continues over time. Every new piece of data makes the model smarter. Techniques like time series analysis, regression models, neural networks, and ensemble methods are commonly used. Neural networks, especially LSTM (Long Short Term Memory) networks, are particularly good at understanding time-based patterns in supply chain data.

5. Real-Time Forecasting and Continuous Learning

Once the model is ready, it starts making real-time predictions. But unlike a traditional forecast that gets updated once a month or once a quarter, an AI system updates its predictions continuously as new data comes in. If a sudden heatwave hits, the system can immediately adjust its forecast for cold drinks, sunscreen, and air conditioning units. This is what makes AI-powered demand forecasting so much more responsive than older methods.

Key Benefits of AI Demand Forecasting in Supply Chain

The advantages of using AI for supply chain forecasting go far beyond just getting a more accurate number. Let us look at the specific benefits that businesses experience when they adopt this technology.

1. Significantly Improved Forecast Accuracy

This is the most obvious benefit. Companies that have integrated AI into their forecasting process report accuracy improvements of 20 to 30 per cent. According to McKinsey research, AI-driven models have cut forecast errors by as much as 20 to 50 per cent in supply chain operations. Better accuracy means fewer surprises, less scrambling, and smoother operations across the board.

2. Lower Inventory Costs

When you can predict demand more accurately, you do not need to keep as much safety stock sitting in your warehouses. Companies using AI-driven demand planning have reported a 20 to 30 per cent reduction in inventory costs according to Gartner and BCG studies. That is money that can be invested back into the business instead of being tied up in unsold products.

3. Reduced Stockouts and Lost Sales

Few things frustrate customers more than finding out that the product they want is not available. AI forecasting helps businesses keep the right products in the right places at the right times. The improved accuracy leads to a 65 per cent reduction in lost sales due to out-of-stock situations, according to McKinsey data. For a large retailer, this can translate to millions of dollars in recovered revenue.

4. Lower Warehousing and Administration Costs

Better forecasting does not just help with inventory. It also reduces the costs of running warehouses and managing the administrative side of supply chain management. McKinsey research shows that warehousing costs can fall by 5 to 10 per cent and administration costs by 25 to 40 per cent when AI forecasting is applied properly. These savings come from more efficient space utilisation, better staffing decisions, and reduced need for emergency shipments.

5. Faster Response to Market Changes

Markets change fast today. A viral TikTok video can create overnight demand for a product nobody expected. A weather event can shift buying patterns in hours. AI systems process real-time data and can adjust forecasts almost instantly. This gives businesses the agility to respond to changes before they become problems, turning potential disruptions into opportunities.

6. Better Workforce Planning

Supply chain forecasting is not just about products. It is also about people. Companies in sectors like telecommunications and energy have used AI forecasting for workforce planning. In these cases, AI-based scheduling has reduced labour costs by 10 to 15 per cent and automated up to 50 per cent of the forecasting and staffing process. This means the right number of workers are scheduled at the right times, reducing both overtime costs and idle time.

Traditional vs. AI-Powered Demand Forecasting: A Comparison

| Feature | Traditional Forecasting | AI Powered Forecasting |

|---|---|---|

| Data Sources | Historical sales data, manual inputs | Hundreds of data sources, including social media, weather, IoT sensors, and economic data |

| Update Frequency | Monthly or quarterly updates | Continuous real-time updates |

| Accuracy Level | Moderate, with error rates of 25 to 50 per cent in some industries | 20 to 50 per cent fewer errors compared to traditional methods |

| Scalability | Limited by human capacity and spreadsheet tools | Can handle millions of SKUs across thousands of locations |

| Response to Disruptions | Slow, often reactive | Fast, proactive adjustments based on real-time signals |

| Human Involvement | Heavy manual effort for data collection and analysis | Automated with human oversight for strategic decisions |

| Cost of Errors | High overstocking and stockout costs | Reduced inventory costs by 20 to 30 per cent |

Real World Examples of AI in Supply Chain Demand Forecasting

Theory is one thing, but real-world results tell the full story. Several global companies have already deployed AI demand forecasting in their supply chains, and the results speak for themselves.

1. Walmart: Building a Smarter Supply Chain with AI

Walmart, the world’s largest retailer, has invested heavily in AI-powered demand forecasting. The company uses a multi-horizon recurrent neural network that was built entirely in-house to predict demand for multiple points in the future. This neural network takes inputs from past demand patterns, planned future events, and current global and local trends to create detailed forecasts.

Walmart’s AI systems analyse data from point of sale systems, weather forecasts, local events, social media trends, and supply chain inputs like supplier lead times and warehouse stock levels. The result is a 360-degree view of demand drivers. If a storm warning is issued in a region, the AI can predict spikes in water, batteries, and emergency supplies and trigger replenishment orders before the storm even arrives.

According to reported results, Walmart achieved a 16 per cent reduction in stockouts, a 10 per cent improvement in inventory turnover, and a 10 per cent reduction in logistics costs through its AI-driven supply chain systems. Projects that once took months can now be completed in weeks thanks to supply chain automation powered by AI.

2. Amazon: AI That Adapts in Real Time

Amazon has built its entire logistics operation around AI. The company uses AI-powered forecasting models that analyse customer behaviour, seasonal patterns, and external factors to predict what products will be needed, where, and when. Amazon has also invested in technologies like Wellspring, a generative AI mapping tool, and new robotics capabilities that use agentic AI systems to handle logistics challenges.

One of the most striking examples of Amazon’s AI capabilities came during the COVID-19 pandemic. When demand for toilet paper surged by 213 per cent almost overnight, Amazon’s AI-powered forecasting system adapted quickly to the new demand pattern, enabling real-time supply chain adjustments. While many retailers were caught off guard, Amazon was able to adjust its inventory allocation and shipping priorities to keep products moving.

3. Levi’s: Reducing Stockouts with Machine Learning

Fashion brands face unique challenges in demand forecasting because trends change rapidly and products have short life cycles. Levi’s implemented an AI-powered demand forecasting solution that creates a dynamic, continuously evolving model. The system learns from new data over time and adjusts its predictions accordingly. The results were impressive: a 15 per cent reduction in stockouts and a 10 per cent increase in inventory turnover.

Recommended Reading:

Industries Where AI Supply Chain Forecasting Makes the Biggest Impact

While AI demand forecasting in the supply chain benefits almost every industry, some sectors see particularly strong results. The adoption rates and impact vary based on the complexity of supply chains, the speed at which demand changes, and the cost of getting forecasts wrong.

1. Retail and E-Commerce

Retail leads the way in AI adoption for supply chain forecasting. With millions of products, thousands of stores, and constantly changing consumer preferences, retailers need every advantage they can get. AI helps retailers like Walmart reduce stockouts by 30 per cent, while e-commerce companies use AI to achieve 92 per cent accuracy in sales forecasting at the SKU level. The retail segment is expected to expand rapidly in the coming years as more businesses adopt AI-driven inventory systems.

2. Manufacturing and Automotive

The automotive segment accounted for the largest market share of 18 per cent in the AI in supply chain market in 2024. Manufacturers use AI to predict demand for parts and components, optimise production schedules, and manage complex global supply networks. Predictive maintenance powered by AI also helps avoid costly production downtime.

3. Healthcare and Pharmaceuticals

Healthcare is one of the fastest-growing segments for AI in supply chains. The sector increased AI adoption by 24 percentage points year over year, jumping from 41 per cent in 2024 to 65 per cent in 2025. Pharmaceutical companies use AI to predict demand for medications, manage cold chain logistics, and reduce drug shortages. The pandemic showed how critical accurate forecasting is in healthcare supply chains.

4. Food and Beverage

Food supply chains deal with perishable products where overstocking leads to waste and understocking leads to empty shelves. AI forecasting helps food companies predict demand more precisely, considering factors like weather, holidays, and local events. Gartner data shows that the median forecast error in food and beverage is around 25 per cent, which AI can significantly reduce.

5. Transportation and Logistics

Logistics companies use AI to forecast shipping volumes, optimise route planning, and manage fleet capacity. AI-powered forecasting helps these companies anticipate demand surges, plan for peak seasons, and allocate resources more efficiently. Route optimisation alone can save significant fuel costs and reduce delivery times.

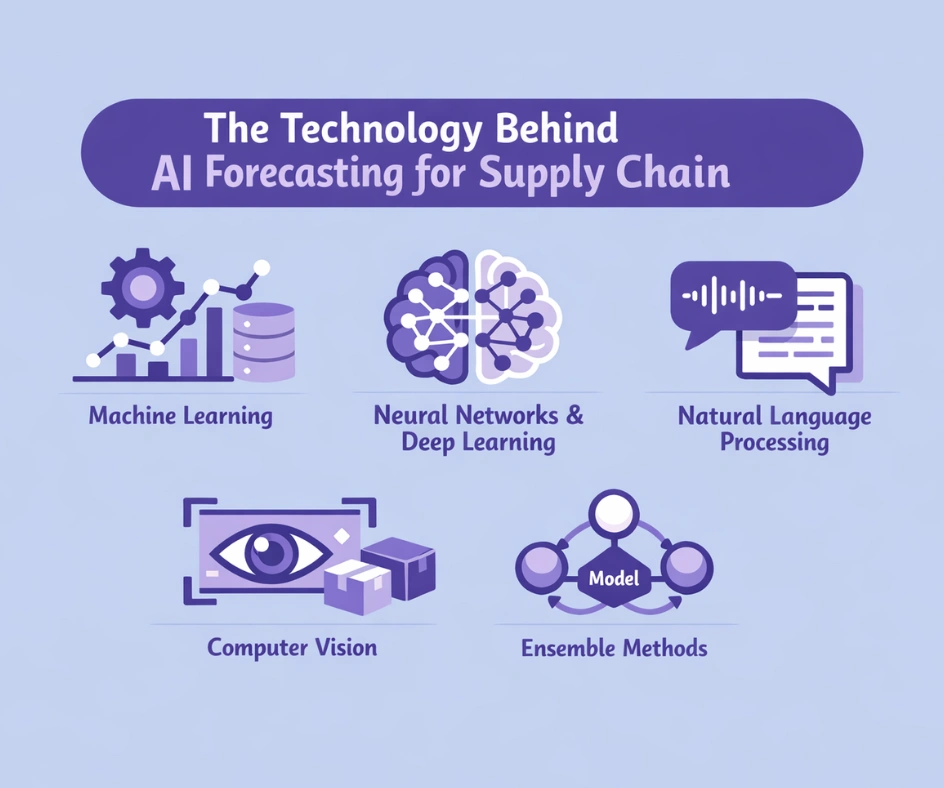

The Technology Behind AI Forecasting for Supply Chain

Several types of AI and machine learning technologies work together to make supply chain forecasting more accurate. Understanding these technologies helps businesses make better decisions about which tools to adopt.

1. Machine Learning (ML)

Machine learning is the foundation of AI demand forecasting. ML models are the most widely deployed AI type in supply chain forecasting, with 87 per cent of enterprises using them for demand forecasting in 2025. ML algorithms learn from historical data and improve their predictions over time without being explicitly programmed for every scenario.

2. Neural Networks and Deep Learning

LSTM (Long Short-Term Memory) networks are particularly effective for time series data in supply chains. These networks can remember patterns over long time periods, making them ideal for capturing seasonal trends, cyclical demand patterns, and long-term shifts in consumer behaviour. Walmart’s multi-horizon recurrent neural network is a prime example of this technology in action.

3. Natural Language Processing (NLP)

NLP is used by 34 per cent of companies in their supply chain operations. It helps analyse unstructured data from sources like customer reviews, social media posts, and news articles. By understanding what people are saying about products and brands online, NLP gives AI forecasting models a sense of consumer sentiment that traditional data cannot provide.

4. Computer Vision

Computer vision technology is used by 62 per cent of companies for quality control in their supply chains. It can also contribute to demand forecasting by monitoring shelf levels, tracking warehouse inventory, and even analysing foot traffic in stores. This visual data adds another layer of information to AI forecasting models.

5. Ensemble Methods

Ensemble methods combine multiple AI models to produce more accurate forecasts than any single model could achieve alone. Techniques like Random Forest and XGBoost have shown 15 to 25 per cent accuracy improvements over individual models. Stacking models, which combine base models with a meta learner, can achieve an additional 5 to 15 per cent improvement on top of the best individual model.

AI Supply Chain Forecasting Impact by Industry

| Industry | AI Adoption Rate | Key Impact Areas |

|---|---|---|

| Retail and E-Commerce | Highest among all sectors | Inventory optimisation, personalisation engines, last-mile logistics, demand sensing |

| Automotive | 18 per cent market share in 2024 | Parts forecasting, production scheduling, predictive maintenance, and supplier management |

| Healthcare and Pharma | 65 per cent adoption in 2025 (up from 41 per cent) | Drug demand prediction, cold chain management, shelf life optimisation, and shortage prevention |

| Food and Beverage | Growing steadily | Perishable goods management, waste reduction, seasonal demand planning, supply coordination |

| Transportation and Logistics | Strong and increasing | Route optimisation, fleet management, shipping volume prediction, last mile delivery planning |

| Manufacturing | Well established | Production planning, raw material procurement, quality control, and equipment maintenance |

Challenges in Implementing AI Demand Forecasting

While the benefits are clear, adopting AI for supply chain forecasting is not without its challenges. Businesses need to be aware of these hurdles so they can plan for them and avoid common mistakes.

1. Data Quality and Integration Issues

AI models are only as good as the data they receive. Many companies struggle with fragmented data stored in different systems that do not talk to each other. In 2024, 29 per cent of firms cited data silos and incompatible IT infrastructure as a major barrier to deploying analytics tools. Without clean, unified data flowing from ERP systems, point of sale terminals, warehouse management systems, and external sources, even the most advanced AI model will produce poor results.

2. Shortage of Skilled Workforce

Implementing and managing AI systems requires people with specialised skills in data science, machine learning, and supply chain management. Finding professionals who understand both AI technology and supply chain operations is difficult. Companies often need to invest in training their existing teams or partnering with external technology providers to bridge this gap.

3. High Initial Investment

While AI delivers strong returns over time, the upfront costs can be significant. These include software licensing, data infrastructure upgrades, integration with existing systems, and training. For small and medium-sized businesses, this initial investment can be a barrier. However, the rise of cloud-based AI solutions and SaaS platforms is making the technology more accessible to businesses of all sizes.

4. Change Management

Introducing AI into established supply chain processes requires significant organisational change. Teams that have been doing things a certain way for years may resist new approaches. Successful AI adoption requires strong leadership support, clear communication about the benefits, and gradual implementation that allows people to adapt.

5. Data Privacy and Security Concerns

AI systems process large amounts of sensitive business data, including sales figures, customer information, supplier details, and pricing strategies. Protecting this data from unauthorised access and ensuring compliance with data protection regulations is a constant concern. Companies need strong security protocols and governance frameworks to manage these risks.

Recommended Reading:

How to Get Started with AI Demand Forecasting

For businesses that are ready to explore AI-powered demand forecasting, the journey does not have to be overwhelming. Here is a practical, step-by-step approach that works for companies of all sizes.

1. Start with a Clear Business Problem

Do not try to apply AI everywhere at once. Pick a specific forecasting challenge that causes the most pain. Maybe it is a particular product category with high stockout rates, or a region where demand is hard to predict. Starting focused allows you to learn quickly and show results that build support for broader adoption.

2. Unify Your Data

Before any AI tool can help, your data needs to be accessible and clean. Bring together data from sales, inventory, marketing, logistics, and external sources into a single, unified platform. This might mean upgrading your data infrastructure or connecting existing systems through APIs. This step takes effort, but it is the foundation for everything else.

3. Choose the Right Model

Different business situations call for different AI approaches. A retailer with millions of SKUs might need deep learning models, while a manufacturer with fewer products might get great results from simpler machine learning algorithms. Cloud-based solutions and SaaS platforms have made it easier for businesses to start with AI without building everything from scratch.

4. Run a Pilot Program

Implementation timelines vary, but pilot programs typically take 3 to 6 months, while full-scale deployment averages 12 to 18 months for enterprises and 4 to 8 months for smaller businesses using cloud-based solutions. A pilot lets you test the technology, measure results, and make adjustments before committing to a full rollout.

5. Scale Gradually

Once you have proven results from your pilot, expand to other product categories, regions, or business units. Each expansion should build on lessons learned from previous stages. Keep measuring results and refining your models. AI forecasting is not a set it and forget it tool. It requires ongoing attention and improvement to deliver the best results.

The Role of Cloud Computing in AI Supply Chain Forecasting

Cloud technology plays a big role in making AI demand forecasting accessible to more businesses. In 2024, cloud-based deployments accounted for 75.6 per cent of the AI in the supply chain market. There are good reasons for this dominance.

Cloud-based AI solutions do not require large upfront investments in hardware and infrastructure. Businesses can subscribe to SaaS platforms and start using AI forecasting tools without building their own data centres. This pay-as-you-go model is especially helpful for small and medium-sized businesses that want the benefits of AI without the massive capital expenditure.

Cloud platforms also offer flexibility. Businesses can scale their AI capabilities up or down based on their needs. During peak seasons, they can increase computing power to handle larger data volumes and more complex calculations. During quieter periods, they can scale back and reduce costs. Major cloud providers like AWS, Google Cloud, and Microsoft Azure all offer AI and machine learning services specifically designed for supply chain applications.

About 47 per cent of small and mid-sized businesses now use affordable AI tools like SaaS forecasting, open source analytics, and subscription-based inventory platforms. This shows that AI demand forecasting is no longer just for giant corporations with unlimited budgets. The technology is becoming democratic, available to businesses of all sizes and across all industries.

The Future of AI in Supply Chain Demand Forecasting

The technology is evolving rapidly, and several trends are shaping the future of AI demand forecasting in supply chain operations.

1. Touchless Forecasting

Gartner predicts that 70 per cent of large organisations will adopt AI-based forecasting to predict future demand by 2030. A key goal is achieving “touchless forecasting”, where AI systems generate accurate forecasts without requiring frequent manual inputs or regular human intervention. This frees up planning teams to focus on strategic decisions instead of spending time adjusting numbers in spreadsheets.

2. Autonomous Supply Networks

The next step beyond AI forecasting is fully autonomous supply networks. These are supply chains where AI does not just predict demand but also automatically adjusts production, inventory, and logistics in response to those predictions. Walmart is already moving in this direction, using agentic AI tools that can detect, diagnose, and correct supply chain issues in real time without manual intervention.

3. Integration with Blockchain for Transparency

Combining AI with blockchain technology creates supply chains that are both intelligent and transparent. AI provides the predictive intelligence, while blockchain provides a tamper-proof record of every transaction and movement in the supply chain. This combination is particularly valuable for industries like food and pharmaceuticals, where traceability is legally required, and consumer trust is essential.

4. Digital Twins

Digital twins are virtual replicas of physical supply chain assets and processes. Companies are using AI-powered digital twins to simulate different scenarios and test the impact of various decisions before implementing them in the real world. This helps businesses prepare for disruptions, optimise their networks, and make better strategic decisions without the risk of real-world trial and error.

5. Generative AI in Supply Chain Planning

Generative AI is adding new capabilities to supply chain forecasting. Instead of just predicting what will happen, generative AI can create scenarios, suggest solutions, and even draft plans automatically. Companies like Oracle and Blue Yonder have already introduced AI agents and cognitive planning tools that use generative AI to automate routine supply chain tasks and provide personalised insights.

AI and Blockchain Implementations That Strengthen Supply Chain Operations

The following project shows how AI and blockchain technologies are already being applied to create smarter, more transparent, and more efficient systems. Each implementation uses the same principles discussed throughout this article, from data-driven intelligence and decentralised governance to automated decision-making and community-driven development.

🤖

AIT Protocol: AI-Powered Decentralised Platform

AIT Protocol integrates AI into a decentralised blockchain framework designed for high transaction throughput. The platform supports demanding applications like finance and supply chains, using AI to automate decisions, analyse data, and predict trends while maintaining cross-chain interoperability and decentralised governance.

Build Smarter Supply Chain Solutions with AI and Blockchain:

Our team of certified AI engineers and blockchain developers builds intelligent systems that connect data, automate processes, and improve decision-making across your supply chain. From predictive analytics and demand sensing to blockchain-powered transparency, we deliver solutions that help businesses forecast better, reduce waste, and grow faster.

Conclusion

AI demand forecasting in the supply chain is not a futuristic concept anymore. It is a practical, proven technology that is already delivering real results for companies around the world. From reducing forecast errors by 30 to 50 per cent to cutting inventory costs by 20 to 30 per cent, the numbers make a strong case for adoption. Companies like Walmart, Amazon, and Levi’s have shown that AI-powered demand forecasting works at scale, helping them respond faster to market changes, keep products available for customers, and reduce the waste that comes from poor predictions.

The market for AI in supply chain management is growing at nearly 39 per cent per year, and the demand forecasting segment is leading that growth. With 87 per cent of enterprises already using AI for demand forecasting in 2025, and Gartner predicting that 70 per cent of large organisations will adopt AI-based supply chain forecasting by 2030, the direction is clear. Businesses that invest in this technology now will have a significant advantage over those that wait.

The good news is that getting started does not have to be complicated or expensive. Cloud-based solutions and SaaS platforms have made AI forecasting accessible to businesses of all sizes. The key is to start with a specific problem, unify your data, run a focused pilot, and scale from there. Whether you are a retailer trying to reduce stockouts, a manufacturer looking to optimise production, or a logistics company working to improve delivery efficiency, AI demand forecasting in the supply chain can help you make smarter decisions, reduce costs, and serve your customers better.

Supply chains have always been about getting the right products to the right places at the right times. AI does not change that fundamental goal. It just makes achieving it much more possible.

Frequently Asked Questions

AI demand forecasting uses machine learning and artificial intelligence to predict how much of a product customers will buy in the future. It analyses data from many sources like sales history, weather, social media, and market trends to make predictions that are much more accurate than traditional spreadsheet methods.

AI improves supply chain forecasting by processing hundreds of data inputs at the same time, finding hidden patterns in data, updating predictions in real time, and learning from new information continuously. This results in 20 to 50 percent fewer forecast errors compared to traditional methods.

Retail, automotive, healthcare, food and beverage, manufacturing, and transportation benefit the most from AI-powered demand forecasting. These industries have complex supply chains where accurate predictions directly affect profitability and customer satisfaction.

Yes. Cloud-based SaaS platforms have made AI forecasting much more affordable. About 47 percent of small and mid-sized businesses now use AI tools for forecasting through subscription models that do not require large upfront investments in hardware or infrastructure.

Pilot programs typically take 3 to 6 months to set up and test. Full-scale deployment averages 12 to 18 months for large enterprises and 4 to 8 months for smaller businesses using cloud-based solutions. Starting with a focused pilot is the best approach.

AI forecasting works best with diverse data, including historical sales records, inventory levels, weather forecasts, promotional calendars, social media trends, competitor pricing, economic indicators, and real-time point of sale data. The more data sources available, the more accurate the predictions become.

Reviewed & Edited By

Aman Vaths

Founder of Nadcab Labs

Aman Vaths is the Founder & CTO of Nadcab Labs, a global digital engineering company delivering enterprise-grade solutions across AI, Web3, Blockchain, Big Data, Cloud, Cybersecurity, and Modern Application Development. With deep technical leadership and product innovation experience, Aman has positioned Nadcab Labs as one of the most advanced engineering companies driving the next era of intelligent, secure, and scalable software systems. Under his leadership, Nadcab Labs has built 2,000+ global projects across sectors including fintech, banking, healthcare, real estate, logistics, gaming, manufacturing, and next-generation DePIN networks. Aman’s strength lies in architecting high-performance systems, end-to-end platform engineering, and designing enterprise solutions that operate at global scale.